MVR Evaporator

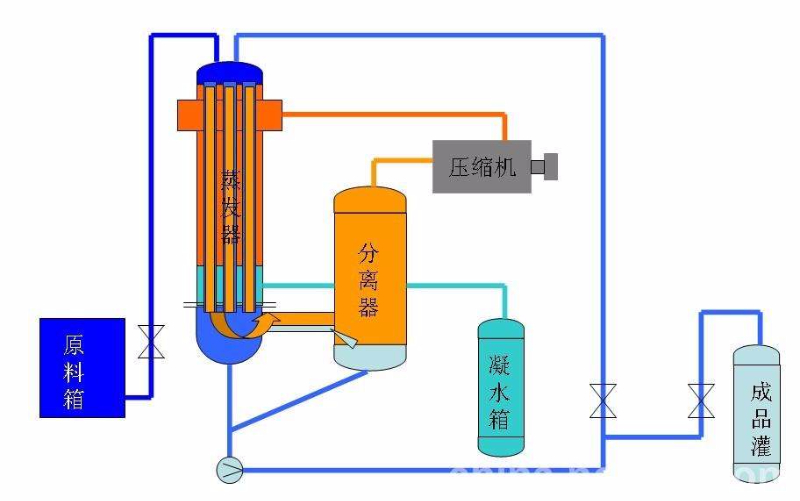

System composition:

It includes heater,separator, compressor, vacuum pump, circulation pump, operation platform, electric control cabinet, liquid level automatic control system & internal valve&pipe fittings, the structure is quite simple.

Working principle:

Its principle is to use high energy efficient steam compressor to compress evaporation of secondary steam, converts electrical energy into heat energy , and improve the secondary steam enthalpy, the improving heat secondary heating steam be feeding into the evaporation chamber for heating, in order to achieve cyclic utilization the existing secondary steam heat, so no need feed external live steam, rely on the evaporator since the cycle to achieve the purpose of evaporation concentration. .Theoretically using MVR evaporators save more than 80% of energy than conventional evaporator, save more than 90% water, reduce more than 50% of floor space.

Main principle: Mechanical vapor recompression MVR evaporator using secondary steam generated in the evaporator, after compressing, the pressure/temperature/ enthalpy increased, and then feed to the heating chamber as heating source, which make the liquid keep boiling, while the heating steam will be cooled into condensate water. In this way, have made full use of the secondary vapor and recover latent heat& improve heat efficiency, live steam economy is equivalent to 30 effect of multi-effect evaporation, reduced the demand of external heating and cooling resources, reduce the energy consumption and reduce pollution.

Main type:

MVR forced circulation evaporator, MVR rising film evaporator, MVR falling film evaporator, MVR split type evaporator.

Main features:

1.The MVR evaporator energy saving technology is the most advanced international technology of evaporator, only need few live steam (When start evaporator need few live steam, during normal running almost no need live steam), which greatly reduce business operating costs, reduce environmental pollution.

2. Due to adopt compressor supply heat source, there is little temperature difference which compared with traditional evaporator, and can achieve moderate evaporation, greatly improved product quality and reduce fouling.

3.No need condenser or only need small size condenser, the structure and process are quite simple, it can be full automatic operation, continuous running, safety and reliable.

4.This evaporator internal system equipped with CIP clean pipeline, which can achieve clean in place, easy to operate and without dead angle.

5. Liquid material can be evaporated under low temperature (50-100℃) in this evaporator, the liquid material is uniform and without running material, not easy coking, material heating denaturation is minimal.

6. Due to use of 100% recycling secondary steam latent heat, completely avoid the use of live steam, so greatly reduced steam consumption.

7. For heat-sensitive materials can be used with vacuum pump, which can be done in close to absolute pressure under vacuum, so as to realize low temperature evaporation, the minimum evaporation temperature can be 50 ℃;

8. Simple process control and automation——Because of the small amount of fluid retention, the falling film evaporator can be change according to different vacuum degree/feeding capacity/ concentration/ temperature , which is the basic conditions for stable quality of products.

9. The handling capacity can be up to 100T/h, with advantages such as small floor space, compact structure, stable operation and so on.

MVR evaporator consist:

Pre-heater: At most of time, the liquid material should be through pre-heater first for pre-heating before getting into evaporator.

Evaporator: The liquid material inside the evaporator heated by steam for evaporation. Choose different type evaporator according to different liquid material features.

Separator(crystallizer): use to separate vapor and liquid, according to different liquid features choose different type separator(crystallizer), such as normal separator, gravity separator, special design separator (crystallizer ).

Vacuum system: Use to keep the whole system vacuum degree, pump some air, fixed gas, liquid entrainment of gas from the evaporator, so as to obtain the whole system stable evaporation process.

Pump: Use to transfer liquid and concentrated liquid. According to different liquid features choose different pumps, such as centrifugal pump, displacement pump,screw pump.

Compressor: Use to compress secondary vapor to supply heating source, improve secondary vapor enthalpy. According to different flow and compression ratio choose different compressor, in the case of pressure rise increase, multistage compressor can be used in series.

Control system: MVR Evaporation system control center, by regular motor speed, control valve,flow meter, temperature and pressure, to realize automatic evaporation, cleaning, stop operations and so on. Automatic alarm, automatic protection system is not damaged, keep dynamic balance.

Cleaning system: Different liquid after period of evaporator, there maybe scaling phenomenon, general speaking, 99% of the scale can be removed by adding chemical solvent, and can use CIP clean in situ or disassemble to clean.

Scope of application:

Mechanical vapor compression(MVR) evaporator, suitable for milk, glucose, organic acid, VC, xylose, pharmaceutical, chemical and biological engineering, environmental engineering, waste recycling, paper making, salt industry for low temperature concentration.

MVR and triple effect evaporation equipment running cost compare:

10T/h Evaporator running cost compare | ||

Name | MVR evaporator | Triple-effect evaporator |

Steam consumption cost | 0.6(material pre-heating steam consumption)t/h×180RMB/t=108RMB/h | 【4.0+0.6(material pre-heating steam consumption)】t/h×180RMB/t=828RMB/h |

Electric charge | 500kw/h×0.80RMB/kw=400RMB/h | 160kw/h×0.80RMB/kw=128RMB/h |

Recovery of condensed water | 10.6t/h×3RMB/t=32RMB/h | 14.6t/h×3RMB/t=44RMB/h |

Operation cost per hour | 108+400-32=476RMB/h | 828+128-44=912RMB/h |

Annual operating cost | 476RMB/h×24h×300day=3427200RMB | 912RMB/h×24h×300day=6566400RMB |

Annual operating cost difference:6566400-3427200=3139200RMB。 | ||

Product type | CSIC centrifugal compressor | Centrifugal blower |

Product picture |

|

|

Compression ratio | Ratio>1.5 | Ratio<1.5 |

Max flow rate | 200T/h | 120T/h |

Compression temperature rise | Sing-class 8-20℃ | Sing-class 6-8℃ |

Impeller form | Three-dimensional flow, Centrifugal type | two-dimensional flow, Centrifugal type |

Impeller fabrication process | Forgings whole milling | Welding |

Impeller material | Forging steam turbine steel titanium alloy | Cast iron、nickel plating/nickel phosphorus |

Fabrication cost | Expensive | Cheap |

Impeller picture |

|

|

Impeller weight | Light, Starting current is small | Heavy, Starting current is big |

Shaft | Tilting-pad | Ball bearing |

Power balance accuracy | High (Without counterbalance) | Low(Welding counterbalance) |

Machining stress | Low | High |

Motor | Asynchronous motor/High voltage motor (Domestic) | Only imported straight motor (Expensive, cumbersome after sale service) |

Quality guarantee | 2years | 1year |

Compression efficiency | >80% | >81%, If tow sets in series, Ƞ=0.81*0.81=0.66 |

Sound insulation/cover | Yes, ≤85dB | No |

After sale service | Within 24hours | Long |

Custom-made cycle | Easy to Custom-made, within 3 months | Difficult to custom-made, need 8-10months |