Scraper thin film evaporator

Work principle:

Scraper film evaporator was used for high-speed rotating liquid distribution into uniform thin film evaporation and distillation of a highly efficient evaporation, distillation equipment, can also be used for deodorization, deaeration reaction, heating, cooling unit operation, etc. This equipment adopts the centrifugal rotor of the sliding groove, is the foreign latest evaporator structure, under the condition of the traffic is very small also can form a thin film,on the inner wall of the cylinder in evaporation processing adhered on the surface of the liquid in the warp can be scraper quickly removed, and compared to fixed clearance scraper evaporator, evaporation can increase 40-69%.

Main features:

1.High values of the heat transfer coefficient, evaporation capacity is big, the evaporation intensity can reach 200 kg/m2.hr, high thermal efficiency.

2.Material short heating time, about 5 seconds to 10 seconds, and work in a vacuum conditions , which is more favorable for heat-sensitive materials, keep all kinds of ingredients do not produce any decomposition, ensure the quality of products.

3.Adapt to wide viscosity change range, both high and low viscosity can be processing, material viscosity can be as high as 100000 centipoise (CP).

4.Change the scraper groove direction of rotation, can adjust the running time of the material in the evaporator.

5.After evaporation section of cylinder precision boring and polishing processing, surface is not easy to produce coking, scaling.

6.Easy operation, product indicators to adjust easily, in an airtight conditions, can be continuous automatic production.

7.Equipment cover a small area , simple structure, convenient maintenance, easy washing.

Using range: applicable to the Chinese and western pharmaceutical, food, light industry, petroleum, chemical industry, environmental protection, etc.

1.Low pressure drop (△P) is the key to the film evaporator advantages: to evaporation materials specified in the state of the steam from the hot face to the condenser, need a certain amount of pressure difference.In general in the evaporator, the pressure drop (△P) is usually high, and sometimes hard to accept.But in the film evaporator gas have bigger through spatial ability, the pressure inside the evaporator can almost as equals the pressure in the condenser, smaller pressure drop loss.

2.High vacuum, low evaporation temperature: as a result of the thin film evaporator low pressure drop, so the film evaporator evaporation process can be in a high vacuum degree and the corresponding low temperature conditions.This feature is especially suitable for low temperature evaporation of thermal sensitive material.

3. Automatic clean heating surface: film evaporator with a scraper, scraper in heating surface sliding, so the liquid film constant agitation and updates, successfully applied to the possible in heating surface fouling material evaporation and distillation.

4. Total heat transfer coefficient is high: because of the liquid film thickness on the surface is one of the most important parameters to control the total heat transfer coefficient , so the use of wall scraper continuous contact, can design controlled easily.

5. Material flow time is short: scraper ends with a certain Angle of groove to push on the heating surface of material liquid spiraling continuously moves down and out of the heating surface.Use this method to minimize the residence time, eliminates the thermal decomposition, polymerization or deterioration.Change the rotor speed or scraper grooved Angle can control the residence time.

6. Strong adaptability, easy to operate: because of the thin film evaporator marked characteristics, which is suitable for stationary evaporation and distillation of thermal sensitive material.So high viscosity material or material viscosity increased dramatically, the increase of concentration of the evaporation process can also smooth operation.

Scraper type:

Due to the movement of the scraper, the materials constantly blowing into a thin film on the surface of the evaporation, the material into a turbulent state, in order to achieve the effect of thin film evaporation.According to the material properties such as viscosity, evaporator can be divided into the following kinds of scraper form:

Activities scraper: it is one of the most basic, the most common form of scraper.Activities in the form of scraper: SR, SL, DR, DL, the drainage groove Angle of 30 °, 45 ° and 60 °.

Fixed scraper: fixed scraper adopts metal materials, it is rigid connection on the rotor, the length of the scraper with evaporation tube body, rotating scraper and evaporation tube body wall gap is only 1 + 2 mm, request high processing and installation accuracy, it is suitable for high viscosity and easy foaming materials evaporation and concentration, desolventizing or purified.

Spiral scraper: the scraper is suitable for poor mobility, easy fouling and high viscosity material evaporation.When the rotor rotates by spiral scraper of thrust, make the concentrated material flow down smoothly.

Hinge hinge scraper: it is suitable for easy scaling on the surface of the heating or medium viscosity material.

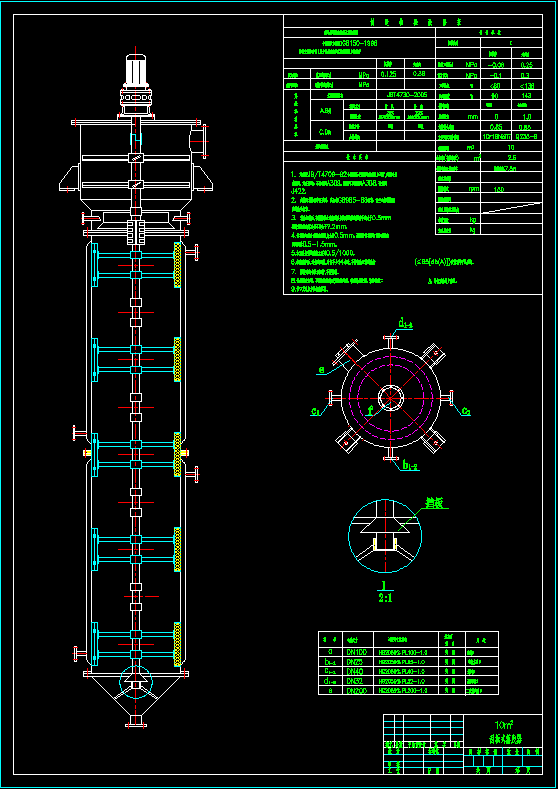

Effective heating area m2 | Main technical parameters | ||||||

Equipment total height mm(A) | Heat cylinder height | Separator height | Bottom seal head height | Heat cylinder diameter mm(Dn) | Jacket diameter mm(Do) | Motor power kw/h | |

0.5 | 2850 | 880 | 500 | 270 | 273 | 377 | 1.1 |

1 | 3500 | 1200 | 650 | 235 | 325 | 426 | 1.5 |

1.5 | 3750 | 1500 | 650 | 250 | 377 | 500 | 1.5 |

2 | 4350 | 1850 | 680 | 315 | 400 | 500 | 2.2 |

3 | 4650 | 2130 | 750 | 330 | 500 | 600 | 4 |

4 | 5500 | 3000 | 750 | 330 | 500 | 600 | 4 |

6 | 6700 | 3660 | 800 | 350 | 600 | 700 | 7.5 |

8 | 6700 | 3600 | 800 | 350 | 800 | 900 | 7.5/11 |

10 | 7200 | 4000 | 850 | 420 | 900 | 1000 | 11 |

12 | 7950 | 4700 | 850 | 420 | 900 | 1000 | 11 |

14 | 8500 | 4500 | 1000 | 580 | 1200 | 1300 | 15 |

20 | 10500 | 5600 | 2000 | 620 | 1400 | 1500 | 18.5 |